Hydrogen internal combustion engine vehicles (HCIV) are believed to be the solution to achieving carbon neutrality. Advancements in hydrogen engines mean that we might see a surge in HCIV, followed by hydrogen fuel stations. In this article, we will look at the combustion properties of hydrogen fuel and the characteristics of an IC engine designed for hydrogen fuel.

Combustion Properties of Hydrogen Fuel

Hydrogen fuel has an energy density of 142.0 MJ/kg, which makes it one of the fuels with the highest energy density when compared to gasoline and diesel, which have energy densities of 45.8 and 45.3 MJ/kg, respectively.

Air-Fuel Mixture Ratio

While gasoline engines operate at a specific air-to-fuel ratio (AFR) or Lambda value with idea or complete combustion at 14.7 and lean mixtures as much as 16.0, hydrogen fuel can operate at higher ratios of lean mixtures. Generally speaking, a lean mixture increases fuel economy and reduces pollutants.

The stoichiometric ratio for hydrogen is 34.3:1 by mass and 2.4:1 by volume.

The ability of hydrogen to be combustible at lean mixture settings is due to its flammable nature, which means lower ignition energy is required for hydrogen combustion. The minimum ignition energy (MIE) of hydrogen is around 0.019 mJ, whereas for gasoline, this number is around 0.1 mJ.

Pre-ignition and Knock

Low MIE increases the risk of pre-ignition when the charge mixture comes into contact with hotspots or surfaces within the combustion chamber, valves, and spark plugs. However, hydrogen has a very high auto-ignition temperature (585 °C), which means only compression does not cause combustion as in diesel engines. Furthermore, the low quenching distance of hydrogen fuel increases the tendency to backfire.

Auto-ignition Temperature

Auto-ignition is a key parameter to determine the compression ratio limit of an engine with a specific fuel type. A comparison of the auto-ignition temperatures of a few domestic fuels is given below. A relatively high auto-ignition temperature of hydrogen means that a high compression ratio can be achieved; on the other hand, it is harder for compression ignition engines such as a diesel engine to work with the hydrogen.

| Gasoline | 246 |

| Diesel | 210 |

| Hydrogen | 585 |

Fuel Metering and Mixture Control

So far, we have learned about the combustion properties of hydrogen fuel. In short, hydrogen fuel is highly flammable (with low ignition energy) and has a short quenching distance. It has properties to sustain lean burn with high auto-ignition temperatures, making it suitable for high-compression engine designs. However, it occupies a larger volume fraction in the fuel-air charge mixture due to its gaseous nature.

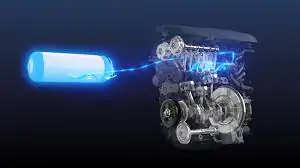

Three types of injection systems are typically used in IC engines: central, port, and direct injection. In the first two types of systems, fuel is injected into either the carburetor or intake manifold, essentially outside the combustion chamber, before the intake valve is closed. Such a system requires less fuel pressure, and the fuel-air mixture has sufficient time for mixing. However, contact of the charge (fuel-air mixture) with the hot intake manifold can cause pre-ignition. Direct injection, as the name implies, injects the fuel into the combustion chamber after the inlet valve is closed, just before the top-dead center (TDC). Direct injection gives more control over the fuel mixture, but the combustion chamber design and position of the spark plugs are critical. The major difference is the very high fuel pressure requirement in direct injection systems. Due to its gaseous nature, hydrogen fuel is less susceptible to non-homogeneous charges, but a dual-spark plug arrangement is preferred.

A direct injection system can greatly reduce the pre-ignition in the intake manifold, but this problem can still occur in the piston. An exhaust gas recirculation (EGR) system helps reduce the overall surface temperature by reducing pre-ignition. However, output power is reduced by an order of 20–30%.

Output Power

Since the stoichiometric ratio of hydrogen is 2.4:1 by volume, it requires 29% of chamber volume. So the amount of fuel being poured is less in a hydrogen engine, and an ideal mixture leads to higher exhaust temperatures and emissions. Low emissions can be achieved by further leaning the fuel, but these parameters all take a toll on the output power. Practically, hydrogen engines will give less output power compared to gasoline engines of the same technology level (fuel injection type, engine block size, ignitor configuration, etc.). So hydrogen engine blocks should have high displacement and force induction systems, such as turbochargers.