Wing design is the most active area of research in aerospace engineering due to its impact on fuel economy. Even minor tweaks in the geometry of the wing can make significant gains in aerodynamic efficiency. Although the phenomena of drag and approaches to mitigation are different in slow-speed and high-speed flight regimes, the governing parameters are almost similar.

Wing optimization can be performed either by selection of airfoil, shape morphing, or geometrical sizing. In this article, we will focus on the geometrical parameters only and understanding the airfoil design is a separate subject that has been covered here A Detailed Guide to Airfoil Geometry It is important to discuss the induced drag, as it is one of the key performance parameter for a 3D wing compared to a 2D airfoil section.

Induced Drag

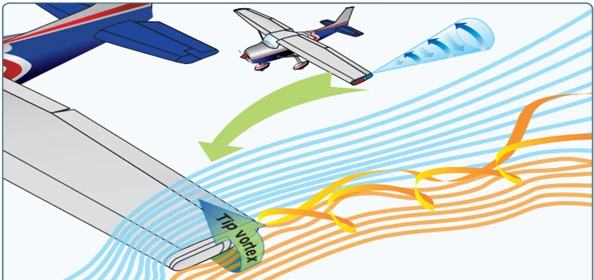

Induced drag is the drag penalty incurred by the 3D flow over the wing because a lift-generating wing has an area of low pressure on the upper surface (the magnitude of low pressure is significant) and high pressure (moderately small compared to ambient air pressure). This pressure difference causes leakage at the tip of the wing, causing flow at the lower surface to curl upward. This abrupt mixing of the flow field generates a vortex wing tip, which, like any separated flow, sucks energy from flow over the wing. These vortices create a wake turbulence hazard for following aircraft, as explained here:

The resulting flow field near the wing surface has a low effective angle of attack because suction from the wing tip vortex causes the flow to bend towards it. This is like inducing a downward component in flow named “downwash.”. The strength of the downwash is proportional to the pressure difference on the wing; hence, proportional to the lift. Therefore, drag caused by tip vortices is called lift dependent drag or induced drag.

It is interesting to note that almost all of the design parameters have significant effect on the subsonic drag (especially, induced drag) except wing sweep, which has major effect on wave drag (drag due to high Mach number or compressibility). Hence, the drag can be reduced by optimizing the geometry of the wing.

Wing Design: Geometrical Parameter

The geometrical parameters of the wing are given below:

- Wing Area

- Aspect Ratio

- Taper Ratio

- Wing Twist

- Wing Sweep

- Wing tip devices (winglets, etc.)

Wing Area

Wing area is a design parameter for aircraft and has a broader effect on aircraft performance in terms of wing loading. Therefore, a holistic analysis of aircraft performance is important, but as far as induced drag is concerned, an increase in wing area will reduce the amount of lift coefficient (CL) required to sustain a given lift.

How Wing Area is Measured

Wing area is defined as planform area or projected area as seen from the top; however, difference of opinion exist on the incorporation of the extended area on the fuselage. For example, Boeing uses Wimpress method to calculate the wing area, which is to extend the leading and trailing edges at same sweep angles till they intersect the plane of symmetry.

The methodology used by the Airbus is to join the starboard (right) and port (left) wing leading and trailing edges by a straight line, respectively. Both methodologies have no advantage or disadvantage as the definition is a mere reference; however, for a comparative analysis of aerodynamic coefficients (The Ultimate Guide to Aerodynamic Coefficients ) it is important to use a similar definition for comparison of the wing designs.

Aspect Ratio Definition

Aspect ratio (AR) in a wing is defined as the ratio of the wingspan to the mean aerodynamic cord. A high aspect ratio wing will have more span as compared to a low aspect ratio wing of the same wing area. AR is broadly a measure of how sensitive the 3D effect of the wing would be as compared to the 2D cross section of the wing (airfoil).

Aspect Ratio of Aircrafts

Aircrafts with high aerodynamic efficiency, such as sailplanes and MALE/HALE UAVs have a higher aspect ratio wing. A fighter aircraft has a low aspect ratio wing due to structural considerations and to reduce transonic wave drag. The aspect ratio of different aircraft categories is given below:

| Name | Aspect Ratio | Class |

| Antares 23 | 38.5 | Sailplane |

| Global Hawk | 35.0 | HALE UAV |

| MQ-1 Predator | 16.5 | MALE UAV |

| Airbus A-350 | 9.3 | Airliner |

| F-16 Fighting Falcon | 3.8 | Fighter Jet |

How does Aspect Ratio Affect Wing Lift and Drag?

The vortex flow not only causes induced drag, but it also has a toll on the lift coefficient at a given angle of attack (AOA). The lifting-line theory approximation of this is given below:

The lift curve slope (CLa) is the sensitivity of a wing section to AOA. It is evident that the maximum value of this slope is for a 2D airfoil of a given cross-section. At low aspect ratio, the wing has a shallow lift curve but delayed stall characteristics; and as AR increases, lift generating behavior of 3D wing resembles that of the 2D airfoil.

It is worth mentioning that the effect on the lift curve is not significant for AR>20 and negligible beyond AR = 30. But the impact of AR is significant over the induced drag; for an aspect ratio of 20 induced drag coefficient is reduced by a factor of 50% and higher values of aspect ratio can further improve the drag number, as shown in the figure below:

Taper Ratio and Wing Twist

It is observed that the effect of induce drag can be further reduced by managing the span-wise pressure distribution. The aerodynamic theory and practical data suggest that an ideal elliptical distribution will have minimal induced drag.

The taper ratio is defined as cord length at the tip divided by cord length at the root section of the wing. The figure below shows the Oswald efficiency factor, which is a proportional factor in the induced drag equation. A value around 0.3 seems to generate the best pressure distribution for most of the wing designs. Wing taper ratios alter pressure distribution, which further change the stall characteristics of a tapered wing.

The practical constraints do not permit an ideal taper ratio most of time. Other techniques, such as a negative twist or washout, is introduced span-wise; in this case, the wing tip is at a lower effective flow angle as compared to the wing root section. Sometimes, manufacturing a “geometrically twisted” wing is difficult; in this case, an “aerodynamic twist” is applied. Aerodynamic twist is achieved by selecting a dissimilar airfoil (typically a low camber airfoil at the tip section) for the root and tip sections, respectively.

Wing Design Sweep Angle

Wing sweep angle is introduced to reduce the impact of supersonic wave drag, which is directly related to the Mach number. The sweep angle is measured at leading edge of the wing, at the quarter cord point (C/4) of the airfoil sections across the wing and at the trailing edge of the wing. The intensity of the shock wave is proportional to the flow Mach number, a swept wing has flow inclined to the leading edge; thus, only a portion of the flow (flow component normal to the leading edge) causes the wave drag.

The quarter cord sweep angle has its own significance, as it is generally the maximum thickness point on airfoil having maximum suction pressure drop on the upper surface of the wing. Imagine this suction pressure standing as a ridge in front of the incoming flow; a swept wing offers a longer path to the flow direction, which means a lower gradient of pressure variation or pressure disturbance.

Wing Tip Devices

A radical solution to treat the wing tip vortex is to incorporate flow effectors such as winglets. These devices are inspired by nature and come in various shapes. The beauty of winglets is that they can be incorporated into an existing aircraft design as well. In recent years, commercial aircraft manufacturers have incorporated “winglets” in wing designs to offer better fuel economy, such as Boeing B-787 and Airbus A-350.

The effect of wing design and shape parameters on aerodynamic performance is discussed; although the contribution of each parameter is straightforward to understand, in real-life situations it may not be possible to optimize each parameter individually. The use of computational fluid dynamics (CFD) in wing design provides a robust approach to this complex problem.